1. Hospitality Industry. 2. Beauty Salons and Spas. 3. Healthcare Facilities....

1. Automated Production Process. 2. Customizable Towel Sizes and Folding Patterns. 3. High-Speed Production and Energy Efficiency....

Introduction. Market Trends. Opportunities and Challenges. Conclusion....

1. Regular Cleaning and Sanitization. 2. Routine Maintenance Checks. 3. Proper Storage and Handling....

Introduction. Step 1: Set Up the Machine. Step 2: Load the Towel Material. Step 3: Start the Production. Conclusion....

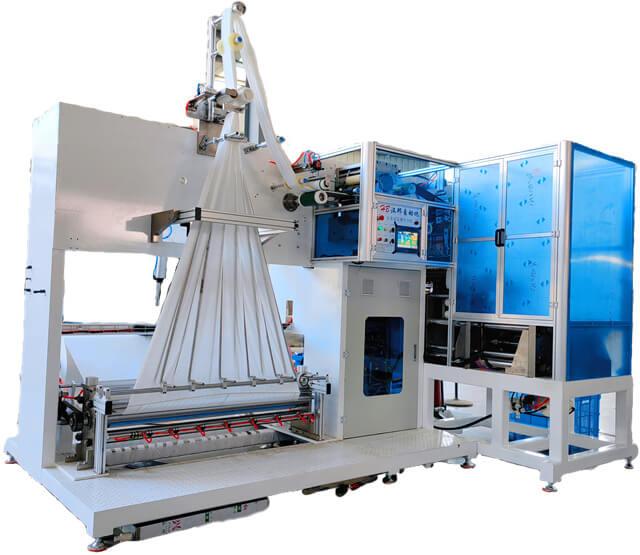

HB is a manufacturer of Compressed Bath Towel Machine,with design, manufacture, and trading as one.It used in the hygiene and personal care industry, providing convenience and efficien...

The non-woven double layer 3D lamination embossing machine is an advanced and efficient device designed for enhancing the quality and appearance of non-woven materials. With its innovat...

2 machines, operated by one person, with a production width of 190mm, 60 meters per minute, and an actual output of 1.2-1.3 tons/machine in 12 hours....

The compressed bath towel machine is an advanced technology that revolutionizes the bath towel industry. This machine utilizes innovative techniques to compress and package bath towels...

The non-woven double layer 3D lamination embossing machine is a cutting-edge technology that has revolutionized the compressed towel industry. With its advanced capabilities, this mach...

In recent years, the demand for diaperproducts has been rapidly increasing in the Philippines. As a result, many local manufacturers arelooking for innovative solutions to streamline ...

Case Study: Korean Client Success in the Compressed Bath Towel Machine Industry Introduction: In recent years, the compressed bath towel industry has witnessed significant growth and ...